When Porus Munshi Came to Discover the Man Behind Su-Kam: My First-Hand Memory of Breakthrough Innovation

Some days, you don’t realize you’re part of something historic until much later.

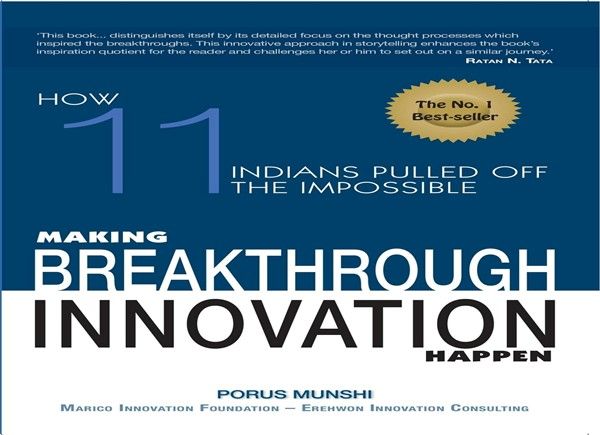

One such day came years ago, when Porus Munshi, a respected author and consultant known for uncovering India’s most game-changing innovations, walked through the doors of our Su-Kam office. At the time, we didn’t know that his visit would result in one of the most powerful chapters ever written on our founder — Mr. Kunwer Sachdev — in his landmark book Breakthrough Innovation.

But I remember it clearly now.

Porus wasn’t just there to collect data. He was there to understand the heart of the company, and more importantly, the soul of the man behind it. And we — the employees, engineers, team heads — had the privilege of watching this story unfold from within.

As someone who worked closely under Kunwer sir, I had seen the grind, the grit, the sleepless nights, and the quiet sacrifices that came with building Su-Kam. But that day, hearing Porus ask deep, thoughtful questions — not just to sir, but to all of us — helped me reflect on something even deeper: this wasn’t just a company; it was a revolution that began with one man’s restlessness.

Porus was fascinated — not just by the scale of the company, but by how it was built. Su-Kam wasn’t born in a lab or a high-rise corporate office. It began in a small workshop, led by a man who didn’t come from the energy sector, didn’t have a business degree, and yet had the mind of a scientist and the heart of a warrior.

He wanted to know: “What made Kunwer Sachdev different?”

And we all had our own answers —

“He never stops thinking.”

“He’ll call us at night with an idea that can’t wait.”

“He’ll ask the questions no one else dares to ask.”

“He believes we can make anything if we just try.”

I could see it in Porus’s eyes — the story was resonating.

The chapter that eventually appeared in Breakthrough Innovation was a masterful reflection of what we saw every day. It captured how Su-Kam, under Kunwer sir’s leadership, managed to disrupt an entire industry, creating world-class power solutions from scratch in a country that was still importing low-quality alternatives. While others followed trends, sir created them.

But what truly made Su-Kam a "breakthrough" wasn't just its products — it was the thinking behind them. Kunwer Sachdev didn’t believe in incremental change — he believed in radical possibility. He encouraged experimentation, tolerated mistakes, and celebrated first attempts. For him, innovation wasn't a department — it was a way of life.

Porus Munshi captured this beautifully. And reading that chapter, even today, gives me a lump in my throat.

Because I lived it.

Because I remember the cluttered meeting rooms where sir would draw new circuit designs on a whiteboard.

Because I remember the pride in our voices when customers told us Su-Kam worked better than anything else.

Because I remember how sir treated every problem like a puzzle waiting to be solved — and every success as fuel to do more.

That’s the real breakthrough. Not just the technology, but the thinking. The refusal to accept things as they are. The belief that we — a team of engineers, thinkers, and dreamers — could take on the world from our little corner in India.

Years have passed since that interview. Porus has gone on to inspire countless with his writing. Kunwer sir, true to form, continues to innovate — now with AI, clean tech, and youth empowerment through his new ventures like Kunwer.ai.

But the message of that chapter — and the feeling I had watching it come together — remains as fresh as ever.

And that’s why I’m sharing it here, on this website. Because some stories must be read again. And again. And again.

Because in a world chasing shortcuts, this is a reminder of what it truly takes to build something lasting — clarity, courage, and a constant thirst to do better.

Read it. Remember it. Let it spark something inside you.

Because the real breakthrough begins when you believe you can.

The Complete Chapter on Kunwer Sachdev from Breakthrough Innovation by Porus Munshi:

A question many budding entrepreneurs ask themselves is: How do I create a new business? The smarter among them ask: What does it take to create an industry? Su-Kam and its founder managing director Kunwer Sachdev are a textbook example of what it takes to create not just a business, but an industry. Beginning with nothing more than an idea and Rs 10,000 as capital, today Su-Kam is the biggest Indian corporate in the power backup industry. Last year they had revenues of around Rs 600 crores. They have a presence in more than 50 countries, employ 1200 people across 23 offices, have 6000-plus network partners, and aspire to touch 50,000 network partners or dealers over the next three years. They have more than 50 per cent market share in the organized sector. So how did Kunwer create an industry where none existed? The first step was of course to spot the opportunity-and it took a different way of perceiving reality to do that. The second was to create a superior product that was clearly differentiated in the market. The third was to create a distribution channel and a

brand. The fourth was to emerge with wave after wave of innovation that left the competition gasping-and in the process of creating these waves of innovation, an industry was created. At every step, what drove success was a continuous focus on world. non-dilution. Everything taken up had to be the best in the As the people at Su-Kam say, their market is not limited to India; it's the global market they are going after.

THE BEGINNING

It home. all began in 1997 when Kunwer bought an inverter for use at The quality was so poor that almost every second day a service person would come over trying to fix its innumerable problems. Since Kunwer had a fair idea about manufacturing electric and electronic systems, being then in the cable TV business and manufacturing the parts for cable operators, he decided to open inverter himself. Though he doesn't have a technical background, what he saw inside made him decide to take on the inverter business. As he says, 'I opened the inverter and saw that industry it could not function the way it was currently made. So the no way couldn't grow because if a product doesn't work there's the industry can grow.’

He saw this as a huge opportunity. Since India is perennially be short sold ofpower, technically every single household in India could an inverter! Also, Indian power conditions no were so bad, India inverter imported from outside could work effectively in India. needed its it own technologically would be able customized inverters that in to handle the frequent and extreme fluctuations conditions. power as well as get charged in very erratic power supply number of small Finally, because the industry was made up of a decided to enter local players, nobody owned the market. He the inverter and power backup industry.

What is amazing is that there were many large players in India in the electrical and consumer durables fields. No one saw an opportunity here.The main block is that many ofthem identified themselves with their existing products alone. But it isn,t 100 difficult for, say, refrigerator manufacturers to figure out that their refrigerators don't work four to five hours every day in most homes across India. If they had looked at what prevents their refrigerators working, they just might have seen a huge opportunity in the electricity storage and generation business.

The first step in creating and owning a new industry is to identify an area where a number of small mom and pop businesses exist in a category that has huge potential demand. A nascent industry always has a huge number of unorganized players until it begins consolidating. Technology and standards in a nascent industry don't really exist. Think of the computer industry in its infancy. Almost anyone could enter it until consolidation began to happen. A number of organizations create new businesses and new business models by organizing the unorganized and by branding the unbranded. There were dozens of small independent booksellers in India until Landmark and Crosswords happened. Hospitals in India stayed independent family businesses till Dr Prathap Reddy came in and created the Apollo chain of hospitals with consistent standards, and people began to trust the institution and the brand rather than the individual surgeon alone.

Having spotted the opportunity, Kunwer began with a small prototype. Along with the engineers from his cable TV business he studied almost all the inverters available in the Indian market in 1997. They realized that all inverters had the same ineffective capacitor technology that made them so unreliable. generators At the time that were preferred to inverters because of the unreliability caused the inverter was Videocon's battery to run down. The only exception inverter. the stable power But this inverter was suitable more for conditions of the developed power is stable so world. In the West, inverters don't need to cope with a wide range of fluctuations. events like Also, most inverters there are used for outdoor batteries are long used boat rides or for camping when car or boat with inverters to run equipment like TVs or successfully microwaves or stereo systems. The first inverter launched by Su-Kam was an improvised version of the Videocon inverter adapted to Indian power conditions.

Inverters in the West are used more as outdoor aids. As a result, some of the premier international companies power solutions already in India for several years either didn't see the huge opportunity or were unable to convince abroad about their principals the opportunity space that existed in India. Most MNCs cannot easily spot an opportunity like this because in their countries they don't have problems like these. So they look at markets in other geographies markets in their from the lens of existing own countries. In the West, inverters limited to the outdoor are largely leisure activities activities don't market. Outdoor leisure much exist in India, ergo: no market exists.

When Kunwer launched his first inverter, he knew his current team of cable TV engineers wouldn't be able to innovate or develop new further technology-and technology was clearly the route to take. He would need to hire others. But who should he hire, and from where? The inverter industry didn't exist as an industry. There were only a few assemblers around. Hiring them wouldn'tThe inverter industry didn't exist as an industry. There were only a few assemblers around. Hiring them wouldn't

lead to breakthroughs in product technology. So finally, scouring across industries, he put together an eclectic bunch of people. Some were from the UPS industry, some from diverse digital product industries, some even from the missile industry. A company working on components for the Agni missile had wound up and the engineers there had nowhere to go. Kunwer enrolled them.

Today, one of his R&D heads is one of the missile people. His head of production is from the automobile industry. This has enabled the team to look for ideas outside the usual electrical industry best practices. For instance, in production they use an assembly and just in time (JIT) delivery system taken from the auto industry.

Perhaps the first step in the move from small-time to big-time is an interest in growing the technology in parallel with growing the business. The market was always there for inverters. Ratherthan meet demand at the lowest common denominator by taking a short-term view of the market and supplying what everyone else was supplying, Kunwer made the shift to developing the industry and its technology by employing highly trained professionals. Those who just made fix-it-yourself inverters stayed small scale. Kunwer made the leap by hiring. developing, and growing in-house technological talent. More importantly, he focused on the growth of the industry. Meeting market demand and ensuring the growth of the industry are two very different mindsets and by no means limited to smaller organizations and nascent industries. If your industry isn't quite growing, most key players in the industry may have succumbed to the temptation of 'serving' the market rather than driving it through innovations.

Once Kunwer decided to drive growth through technology, he sourced the MOSFET technology from abroad and the next Oxide inverter they made in 1998 was based on this. MOSFET (Metal Semiconductor Field-Effect Transistor, a device used to amplify the or switch electronic signals) meant that they could reduce size of the inverter to one-fourth, thereby reducing costs, improving of two. With efficiency and enabling them to use one battery instead the MOSFET inverter, Kunwer and his team created a differentiated, the inverter, as superior product. They had crashed the costs of well as set a reference point of what is possible.

DISTRIBUTION AND BRANDING

When Su-Kam came out with the reliable MOSFET inverter, many local manufacturers neither were in a dilemma; they could match they couldn't Su-Kam's price nor quality. Kunwer made them an offer change the refuse. He told them that he was going to radically technology They had two choices: year on year starting with the MOSFET. either match his innovations the market, to stay in or join him as distributors 'In every or dealers. As he says, city there were dozens of people manufacturing inverters. and And there were two kinds of people: manufacturers battery dealers. I converted the manufacturers distributors, into and the battery guy into dealers, and we created a network!

Look at the way the industry began to consolidate Kunwer. The under unbundled unbranded, players began to get bundled and an levels indifferent product began to acquire increasing of technology through innovations to drive differentiation and quality.

Building a business from the ground up, where no industry existed wasn't easy. In the move from unorganized industry to organized, there were a lot of challenges. They had to create and train sales and service people from scratch. They had to get people from other industries, train them, inspire them and send them into the field. They began channel meets and dealer meets and began to educate the dealer and distributor about the product attributes. It was a period of great effort but it laid the seeds for new industry.

Su-Kam needed to build a highly visible brand with minimal advertising expense. Again Kunwer needed to think differently. When he saw that Airtel had put its banners on all possible walls and pillars,he thought ofsome place which had not been targeted by anyone. In 2000, Kunwer was the first person to put up banners of Su-Kam on almost every single dhaba or tea shop that lined the length of all major highways. This gave Su-Kam immediate visibility. But the challenge was that the shop owners would remove the hoardings sooner or later as the boards were not important to them. Kunwer came up with a win-win proposition. He put the names of the dhabas too on the banner/board so that not only did Su-Kam get publicity, but the individual dhaba owners got it as well. He reiterates that he is the first person to start this at this scale and it has now become fairly common, but he got tremendous mileage out of it.

Su-Kam was also the first in the power backup industry in India to start strip advertising in the classified columns to save costs. He'd take up nearly half a page of classifieds and make a large 'Su-Kam' out of it as a half-page of classifieds was much cheaper than buying a regular half-page ad. He then moved on to colour and electronic media advertisements. As he says, many newspapers changed their classifieds policies because of him. Advertisements were placed in newspapers until Su-Kam became a household name known for brilliant technology and dependable products.

THE PRODUCT INNOVATIONS

With the brand building and channel development, product innovations were going on simultaneously. Su-Kam launched a new innovation almost every year. As Kunwer says, 'I change my whole product within a year. The moment the current product is ready I start working on a fundamentally different second product. And does he systematically kill the product after three to four years? 'I try to kill it, sometimes it is killed itself. Even if my earlier product is more successful that the current one, I see to it that it is not manufactured after a couple of years, irrespective of whether the market kills it or not. Why?

Contrast and this with the hawk-eyed manner in which most brand category managers watch out for cannibalization. Their bread and butter, not the organization's, cannibalization depends on can to prevent not happening and they do everything they context: it. We love Peter Drucker's question in this 'What are you going to systematically next three years?' abandon in the Many organizations successful fall in love with their polishing products and spend a lot of time and effort in extent that and improving them and focusing on them to the Sure they go they stop focusing on creating the next big thing. would about working on new ideas, but not the way they the next if their couple current cash cow were going off the market in systematic of years. Drucker's question advocates abandonment breakthroughs so that you are forced to create new before the market shifts catch you unawares.

Because I want to drive the market-I don't want to be driven by it. In every case people who became leaders never thought of changing and when change came in from the outside, they were stuck. My guiding principle is: change the market before it changes you!

Su-Kam is the only organization in the industry with an R&D unit certified by the Department of Scientific and Industrial Research (DSIR), Government of India. The R&D facility at SuKam has state-of-the-art equipment for testing and developing products.

Kunwer's attitude towards the market is one of constant movement. As one of the members of the R&D team put it, 'Whatever we launch anybody will copy it, or will arrive at that platform in the next two to three years! Hence, the underlying philosophy at Su-Kam, in the words of another R&D employee is, 'Regular production should be there but focus should be on next couple of years. What we have developed will continue for the next three years, but after that the product will be obsolete. So you have to be ready with the product for the next three years. And then on to the next three years!

As you can see, Kunwer's attitude has permeated the organization. What more could a leader ask for?

The challenge that Su-Kam faces is that its output is not clearly visible to the end consumer. Su-Kam's constant focus is to provide purer and purer power. It has become a passion to provide the best quality of power of possible. As Su-Kam's director of Operations, Naresh Kaushik, says, Today you don't know on what kind of power supply your fridge and TV are running. And maybe equipment that should have run for six years without breaking down is running only for three years and you are still happy. It's a happiness born out of an ignorance of what is possible. When you put an inverter in your house you don't know how much electricity it uses. For example, it gives you backup for four hours, but to have that backup you never know how much electricity it has taken from the main supply. Maybe it has taken for ten hours and since you don't know how your electricity bill is rising, you are content.

Innovation at Su-Kam, then, has been a constant search to add differentiate value through driving technology as well as to find a way to externally for the consumer. It has come out with innovations differentiation. almost every year to drive value as well as India's

After the MOSFET inverter in 1998, in 2001, Kunwer launched first sine wave technology inverter. The existing gives technology then was the more primitive square wave. Sine wave a pure form of power that can run sensitive appliances. This technology wasn't new to the world, but Indian power conditions have inconsistent fluctuations. surges and huge voltage the technology Hence, using sine wave here required customizing it without a lab? to suit India. But how do you even begin testing Kunwer and his team identified conditions two extreme and places to test and develop the technology for the India. two Meerut and Kanpur had the dubious honour of being fail, places in India where any inverter would consistently thanks to rampant power fluctuations. live laboratories. These became his The technology was developed and tested till finally, a successful inverter the irritating humming was made that not only eliminated sound that inverters made but also transformed the quality of the power produced.

THE PLASTIC BODY INVERTERS

Launched in 2002, the plastic body inverters in India, but also were not just unique in the world. All inverters at the time were made of metal, because the temperature on usage would go up to 120 degrees and there was no other material that could withstand such high temperatures. He knew that using plastic would make an inverter visually appealing, lighter in weight and shockproof as well. So what Kunwer had to do was find a plastic that would not melt. He found his answer with GE Plastics. They developed a plastic for him that was stable at high temperatures. And suddenly the customer had a range oflightweight, attractive inverters to choose from.

When Kunwer approached GE, he went not only with a working model of the inverter but also with a mould predesigned by another Indian manufacturer. GE had only to supply the right kind of plastic. With that was made the world's first plastic-body inverter. There were of course voices of doubt. How could an inverterbe made of plastic? The industry thought Kunwer had lost it. But the market and customers loved it. It was a hit. So, as usual, the competition began copying it. But they copied what they saw, not what went behind the making of the Su-Kam inverter-the intense testing and the backing of a large reputed material supplier. The competition began making inverters with plastic, and the inevitable happened: they started melting. Complaints began pouring in and the governments of UP and Punjab intervened to test the plastic-body inverters of all companies. Only one company cleared the tests and was allowed to continue manufacturing plastic inverters: Su-Kam.

THE HOME UPS

In 2003 came the next success for Su-Kam, when Kunwer decided to integrate two separate power backup devices, the inverter and the UPS, to make, as he says, the first-in-the-world 'Home UPS Such an integration would help in two ways:

1. If a UPS was to work as an inverter, the power backup duration would grow exponentially-from minutes 10-15 to 2-3 hours!

2. Ifan inverter was to work as a UPS, the power produced would be consistent and even more pure than the one provided by the grid. In addition, the switchover time (time taken by the power backup device to switch on after the power goes off) would reduce from 50-100 milliseconds to 0-5 milliseconds. This would be good for every single electrical equipment in the house.

There were tremendous cent, while benefits too. A UPS was taxed at 4 per an inverter was taxed at 12 per cent. By creating a he home leveraged UPS, Kunwer came under the 4 per cent bracket. Something he leveraged to cut the pieces of his product further.

Again to cut the prices of his product further. the inevitable happened. copy the product The entire industry tried to didn't bother to do to reap the tax benefits, but as before, they time. They what Kunwer had done: reduce the switchover just began branding their inverters government as home UPS. The got suspicious and got the products tested. Again all but Su-Kam failed.